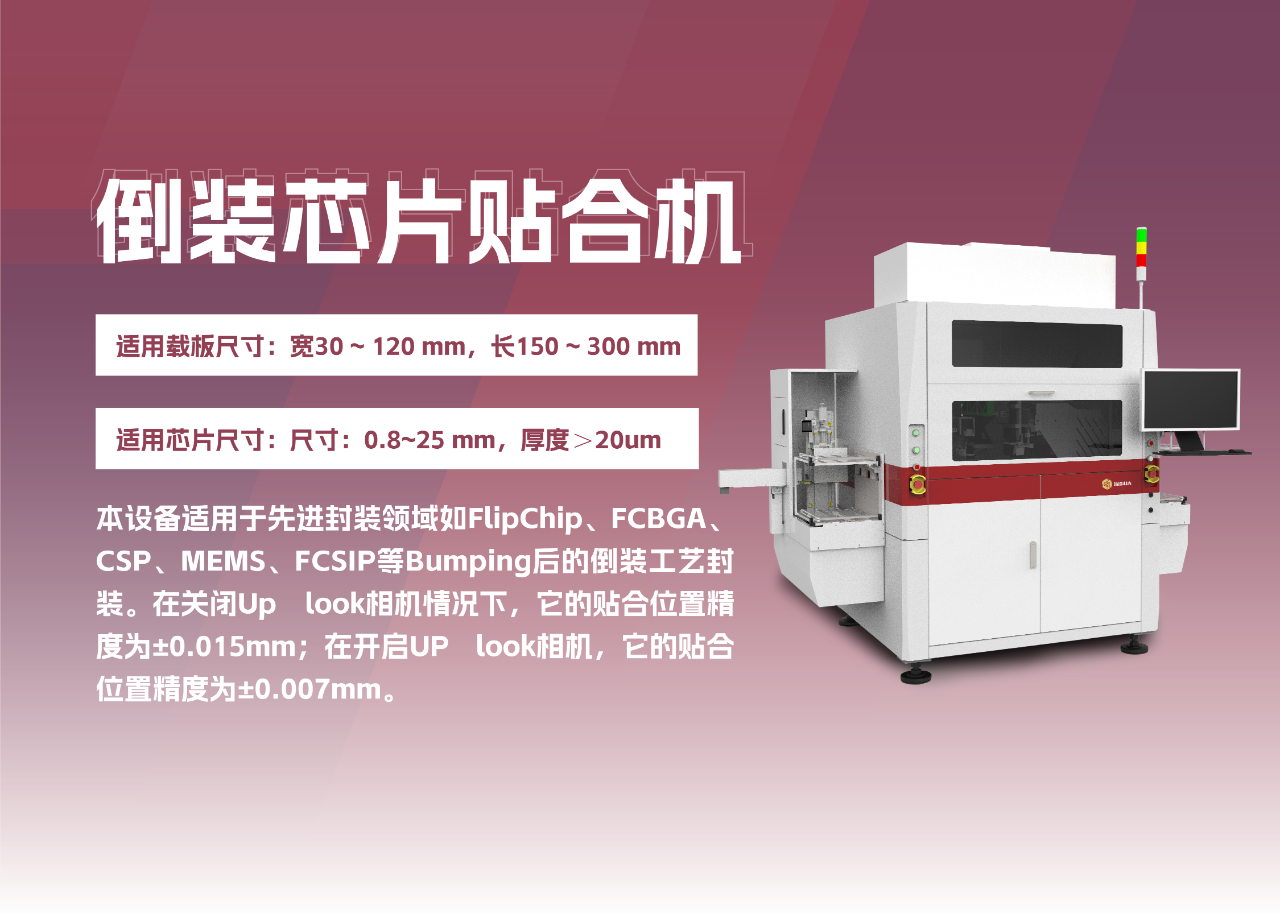

精品推荐 | 倒装芯片贴合机

2023-11-08 16:17

优点介绍

Advantages

热亲和柔性设计,高效贴装无极限

设备整体采用热亲和柔性设计,在保证产品整体产能的同时,能极大提高产品的贴装精度;在关闭UP LOOK相机的情况下,设备产能可达5000PCS/h以上,在开启UP LOOK相机的情况下,可达3000PCS/h以上,同时它能保证贴合精度在±7μm(3δ)之内。

一机多能,兼容三种封装工艺

设备兼容芯片正装、芯片倒装、芯片堆叠封装三种封装工艺;配备摆动旋转机构和翻转机构,使设备能同时兼容正装和倒装两类不同的贴装工艺。配备UplookAlign和Postbond功能,Postbond功能支持实时动态检测和动态补偿,进一步确保了产品贴装的精度和稳定性。

The device is compatible with three packaging processes: chip forward packaging, chip flip packaging, and chip stacking packaging;Equipped with a swinging and rotating mechanism and a flipping mechanism, the equipment can be compatible with two different mounting processes: forward and reverse. Equipped with UplookAlign and Postbond functions, the Postbond function supports real-time dynamic detection and compensation, further ensuring the accuracy and stability of product placement.

自动调宽与升降,封装无忧虑

支持轨道宽度自动调节,以兼容不同宽度的载板。轨道平台拥有基准高度调节和快速升降功能,分别用于堆叠封装时的高度自动调整和有加热需求时的过热脱离。

Support automatic adjustment of track width to be compatible with carrier plates of different widths. The track platform has reference height adjustment and fast lifting functions, which are used for automatic height adjustment during stacking packaging and overheating detachment when there is a heating demand.

多尺寸兼容,快换治具任你选

兼容性强,可快换治具兼容6吋、8吋和12吋晶圆,也可使用快换治具兼容华夫盘或Gelpack上料。

Strong compatibility, quick change fixtures are compatible with 6 inch, 8 inch, and 12 inch wafers, and can also be used for wafer or Gelpack loading.

多元配置,工艺需求无遗漏

前轨道支持正装中转、反装蘸胶、下相机对位等多种配置,以适配客户不同的工艺需求。

The front track supports various configurations such as forward transfer, reverse dip glue, and lower camera alignment to meet the different process requirements of customers.

多段电流保护,快速稳定

载板压板和载板夹爪采用多段电流控制系统,在保证快速下压和快速夹紧的同时,有效降低对载板的冲击。

The load plate pressing plate and load plate clamping claw adopt a multi-stage current control system, which ensures fast pressing and clamping while effectively reducing the impact on the load plate.

创新设计,高效便捷

助焊剂大小及厚度通过前方的槽大小及深度控制,助焊剂刷取板采用无螺钉设计,可以通过拉取直接实现快换;同时,高惯量比动力,可实现每小时3000次助焊刘送料。

The size and thickness of the flux are controlled by the size and depth of the groove in front, and the flux brush plate adopts a screwless design, which can be directly replaced by pulling; High inertia ratio power, able to achieve 3000 times of auxiliary welding and feeding per hour.

智能感应,适应面广

助焊剂仓带缺料感应装置,当助焊刻所剩量不足时,会闪烁黄灯并在人机窗口提醒人工注入助焊刻;其中蘸胶最小0.5*0.5mm,最大20*20mm。

The flux bin is equipped with a shortage sensing device. When the remaining amount of flux is insufficient, a yellow light will flash and remind manual injection of flux in the human-machine window; The minimum amount of glue dipped is 0.5 * 0.5mm, and the maximum amount is 20 * 20mm.

自定义路径,满足需求,点胶更灵活

自研自定义点胶路径编辑系统,客户可根据实际需求绘制所需画胶路径。

Self developed custom dispensing path editing system, allowing customers to draw the desired dispensing path according to their actual needs.

贴合相机模块,热亲和与柔性设计,气冷精准定位

移动支座和位置检测部分采用热亲和设计和柔性设计,极大程度避免了由温变导致的精度丢失,同时加装了气冷流道装置,进一步降低温升,以保证对位精度。

The mobile support and position detection parts adopt a hot affinity design and flexible design, greatly avoiding accuracy loss caused by temperature changes. At the same time, an air-cooled flow channel device is installed to further reduce temperature rise and ensure alignment accuracy.

降低误差,精准贴合

邦头水平移动结构的支座和位置检测部分采用热亲和设计和柔性设计,降低了电机温升带来的误差,保证了贴合精度。

The support and position detection part of the Bangtou horizontal moving structure adopts a hot affinity design and flexible design, reducing the error caused by motor temperature rise and ensuring the fitting accuracy.

精准力控,自适应软着陆

自适应软着陆式邦头力控系统,确保邦头在快速拾取+贴合的同时,消除拾取和贴合过程中速度变化带来的冲击,从而确保拾取和贴合力的精度,在250gf以下力控误差低于5%。

精准调节,完美贴合

Bondhead 齿轮式水平调节装置调节水平如同上发条一样便捷与精准;保证贴合面完全与贴合基准面重合,完成对超薄芯片的无损贴合。

The level adjustment device of the Bondhead gear type is as convenient and accurate as the upper spring for adjusting the level; Ensure that the bonding surface completely overlaps with the bonding reference plane, completing non-destructive bonding of ultra-thin chips.

轻摆臂+铸铁支撑,振动小,取放快

轻量化摆臂+铸铁支撑立柱,保证了高频快速取放料的同时,有效降低了高速摆臂造成的振动,确保了设备的整体稳定性。

The lightweight swing arm and cast iron support column ensure high frequency and fast material collection and discharge, while effectively reducing the vibration caused by high-speed swing arms, ensuring the overall stability of the equipment.

直驱顶针,精度更高,响应更快

直驱式顶针机构,相对凸轮机构精度更高,响应更迅速,且其顶出距离,顶出高度,顶出速度均可设置。

The direct drive ejector pin mechanism has higher accuracy and faster response compared to the cam mechanism, and its ejection distance, ejection height, and ejection speed can be set.

双驱动协同,精确微距,高效保护

双驱动装置,可使顶针与顶针吸盘独立进行微距运动,相互配合下,能有效保护产品,提高生产效率。

The dual drive device allows the ejector pin and ejector pin suction cup to independently move at a macro distance, and in combination, it can effectively protect the product and improve production efficiency.

多顶方案,超薄无忧

当需要分离超薄芯片时,头部可更换为多级顶针剥离装置,最小可剥离30um厚度芯片。

When it is necessary to separate ultra-thin chips, the head can be replaced with a multi-level ejector pin stripping device, which can strip chips with a minimum thickness of 30um.

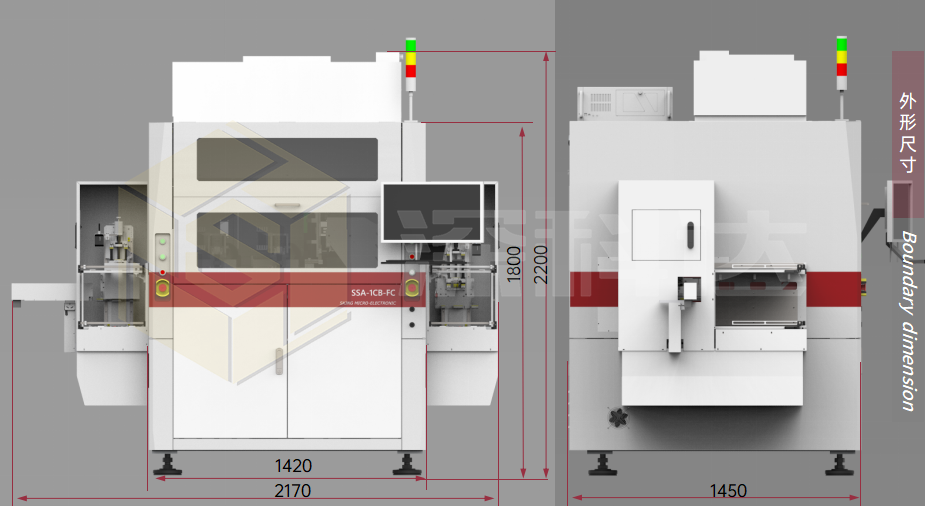

设备外形

Equipment appearance

相关新闻