精品推荐 | IGBT多芯片贴合机

2023-08-21 15:03

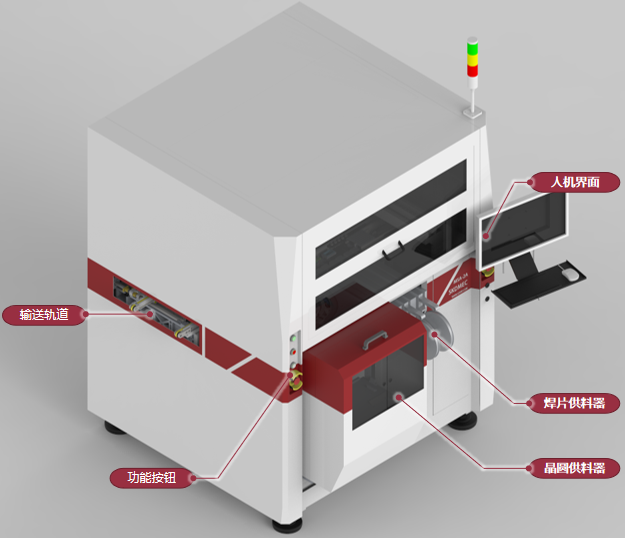

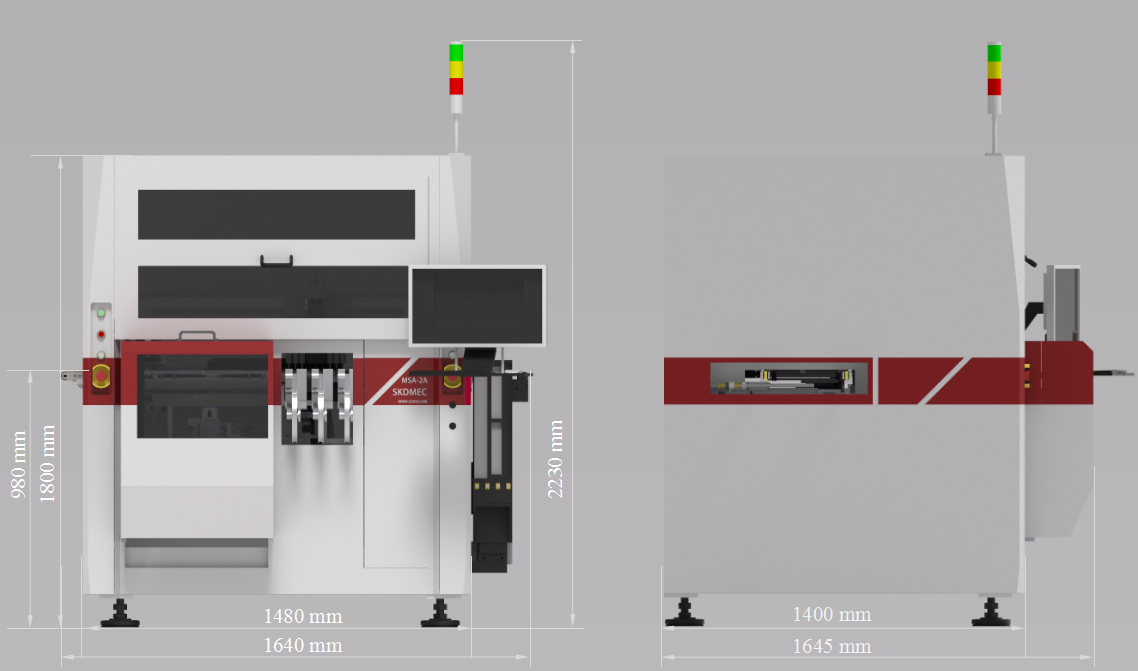

设备外形(Equipment Appearance)

总性能优势(Performance Advantages)

精度高,产量多

贴合位置精度±10μm,角度精度±0.1°,且满足3δ标准。每小时产量可达2000,以标准单颗产品贴一个焊片+一个芯片为基准,设备单次取贴片时间可控制在0.9s以内。

Bonding accuracy is ±10μm, Angle accuracy is ±0.1°. The UPH is 2000, with a solder preform and a chip as the benchmark, the cycle time of equipment is within 0.9s.

兼容性强,能兼容多尺寸晶圆盘

可兼容12寸、8寸、6寸及4寸晶圆盘来料,同时兼容Tray盘来料。

Be compatible with 12 inch, 8 inch, 6 inch and 4 inch wafer, and compatible with Tray.

力控范围大,误差小

力控范围40~1000gf,力控误差在250gf以下能控制在5%以内,250gf以上则可控制在10%以内。

Bond Force is 40~1000gf, the deviation is within 5% (below 250gf) and is 10% (higher 250g).

组件结构的特色(Modules)

绝对值编码器,省时省力

轨道调宽机构使用带绝对值编码器的伺服电机进行驱动,便于一键切换来料载盘尺寸,减少人工调节的时间。

The index width is adjustable by servo motor that to load different size tray, also decrease conversion time of package.

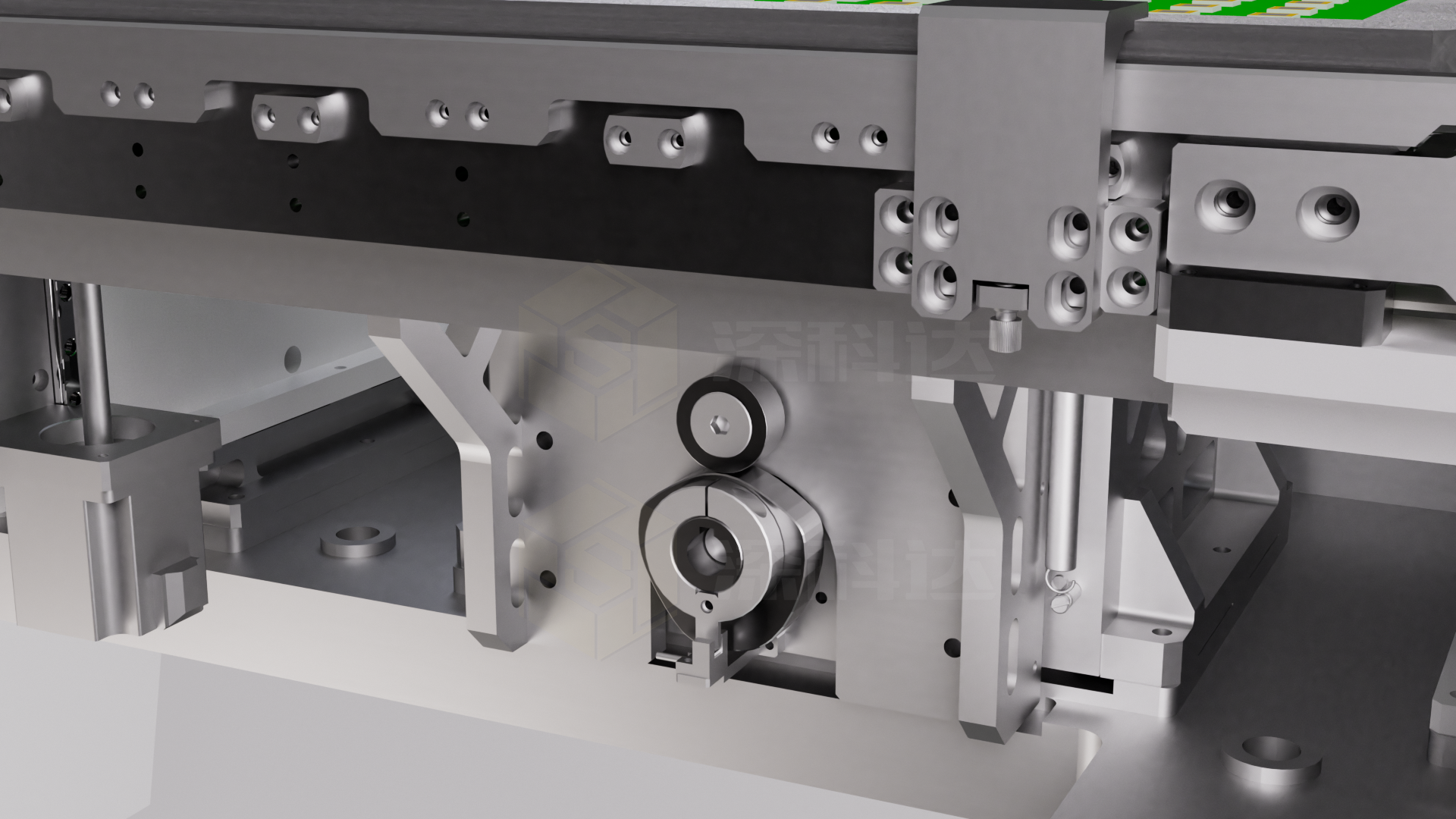

多段谐波凸轮,冲击小,低风险

载盘抬升使用多段谐波凸轮,减少了传动链,加快了升降机构的响应速度,同时谐波凸轮曲线减少了载盘上升或下降过程中的冲击。弹簧升降导杆使得载盘到上升限位时能够缓慢过渡,降低了对载盘上表面的冲击,也降低了由于升降冲击振动,而致使产品贴合偏离的风险。

The multi-stage harmonic CAM is used to reduce the drive chain and speed up the response of the lifting mechanism, while the harmonic CAM curve reduces the impact during the lifting or lowering of the plate. The spring lift guide allows a slow transition from the carrier to the lift limit, reducing the impact on the surface of the carrier and reducing the risk of product fit deviation due to lift shock vibration.

龙门双驱结构,快速又稳定

贴合邦头Y轴采用龙门双驱结构,在保证速度的同时,提高了运行的稳定性;龙门机构底座采用整体铸铁结构,降低了运行时振动的影响,整体精度进一步提高。龙门X/Y轴电机外附气冷装置,降低了长时间运行温变带来的精度影响。

The Y axis of the bond head adopts the double drive structure of gantry, which ensures the speed and improves the stability of operation. The base of the gantry mechanism adopts an integral cast iron structure, which reduces the influence of vibration during operation and further improves the overall accuracy. The external air-cooling device of Gantry X/y axis motor reduces the influence of temperature variation caused by long-time operation.

自动更换芯片顶针和吸嘴

设备支持自动更换芯片顶针和吸嘴,芯片吸嘴库最多可存放12个吸嘴,顶针帽库最多可存放6种顶针帽,独创的摆臂式顶针更换装置,相比同类设备,更换时间节省60%,最多可支持同一型号产品4种不同芯片同时贴装,极大加强了工艺可行性的容度。

The device supports automatic replacement of chip thimbles and nozzles. The chip nozzle library can store up to 12 nozzles, and the thimble cap library can store up to 6 types of thimble caps. The innovative swing arm thimble replacement device saves 60% of replacement time compared to similar devices, and can support up to 4 different chips of the same model product to be installed simultaneously, greatly enhancing the capacity of process feasibility.

相关新闻